|

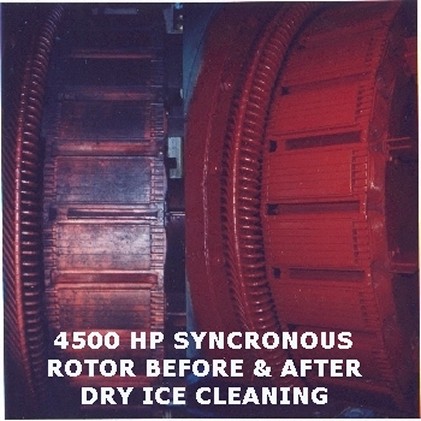

MOTOR, GENERATOR & SWITCHGEAR CLEANING

No Moisture, No Dryout, No Corn Cobs

Motors or genereators, switchgear, stator or rotor windings, armatures or field poles, AC or DC: dry ice cleaning is established as the safest, most economical method to clean rotating electrical equipment. Winding contaminates such as oil, dried paper, dirt, dust and carbon are easily removed with non-conductive, non-abrasive, moisture free dry ice cleaning.

Cryo Services was started in 1995 to utilize dry ice cleaning technology to clean large motor windings. Our staff has 25 years of rotating electrical repair service.

Motor windings show significant megg-ohm and PI test improvements along with decreases in operating temperature after dry ice cleaning. One rule of thumb suggests for every 10 degree Celsius rise in operating temperature, a motor's operating life is reduced by half. Periodic cleaning can reduce motor temperatures and help discover problems such as loose connections or wedges, embrittled insulation, clogged vent holes, and corona damage.

Our dry ice cleaning equipment has been successfully utilized to clean switchgear, transformer bushings, breakers, relays, distribution buss and substation components. We have specific nozzles desigend for electrical cleaning.

|

|